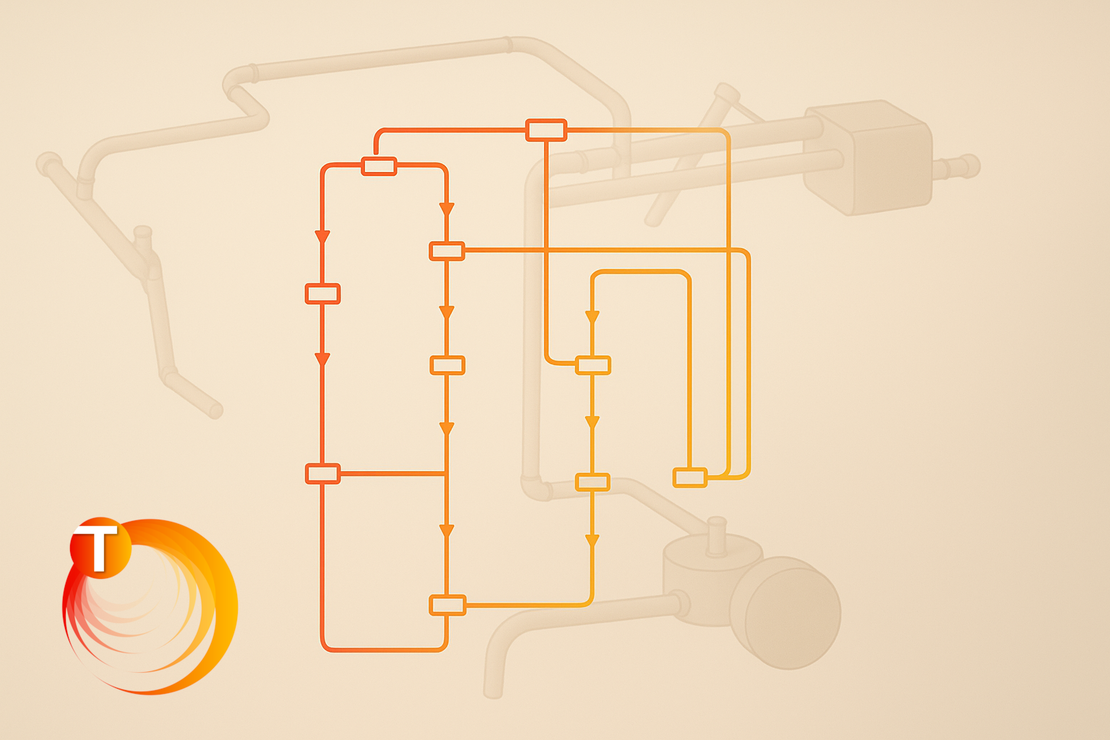

In product concept design, it is vital to comprehend the overall temperature profile of the product and the energy transfer between its components, rather than solely focusing on the temperature distribution within individual components. To address this, there is a demand for a simulation method that can efficiently simplify and expedite calculations while maintaining an acceptable level of accuracy. The lumped-parameter thermal network (LPTN) method effectively meets these criteria, and the principle behind this method is illustrated in Figure 1.

As shown in Figure 1, the physical properties of a system within a control volume are aggregated at the nodes (a, b, c, d, and e). The temperature at these nodes is a representation of the overall temperature of the system. These nodes are interconnected through heat transfer pathways, forming an intricate thermal network. Along each path, thermal resistance, analogous to electrical resistance, acts as the resistance to the energy transfer process. The simplification and modelling of the system is possible using the thermal network method.

Nodes and thermal resistance are the basic components of the LPTN method. This method further depends on the mode of heat transfer and other physical scenarios.

Classification of Nodes

In LPTN, nodes represent the physical properties of the system within a control volume, including volume, mass, material properties, and temperature. Nodes can be classified into three types depending on their heat capacity, and they are:

- Surface Nodes: Represent a surface with zero volume and, consequently, zero heat capacity.

- Volume Nodes: Represent the bulk of a control volume, aggregating its physical properties (mass, volume, material properties). They possess finite heat capacity and store thermal energy.

- Boundary Nodes: Represent an environment or thermal source with a fixed temperature. Since their temperature remains constant regardless of heat exchange, they are considered to have infinite heat capacity.

Thermal Resistance

Thermal resistance depends on the mode of energy transfer. The mode of heat transfer can be categorized into four types:

- Conduction

- Convection

- Radiation

- Mass Transfer (special case)

The first three modes of heat transfer, conduction, convection, and radiation, are governed by the fundamental principle of energy flow from regions of higher temperature to regions of lower temperature, driven by temperature gradients. The fourth mode is unique, relying on mass transport rather than temperature gradients. Thermal resistance calculations are detailed in the next section.

Control Equations and Thermal Resistance Calculation

Control Equations

For each discrete node in Figure 1, the energy conservation principle holds:

where Qij represents the heat flux between node i and node j in Watts [W]; i.e., the energy transfer between nodes i and j. It is to be noted that the energy flowing into node i is negative, and the energy flowing out of node i is positive. Here, Si, is the heat source to the node i in W; ri, Vi, Cpi, and Ti are the density in kg/m3, volume in m3, specific heat capacity in J/kg.K , and temperature of the node i in K, respectively.

The meaning of equation (1) is that the net energy flowing into node i equals the energy stored in node i. For a steady-state problem, where the temperature does not change with time, the right side of the equation will be zero.

The expression for heat flux between nodes i and j is (analogous to current = voltage difference/resistance):

where Rij is the thermal resistance between nodes i and j, representing the resistance to energy transfer.

Thermal Resistance Calculation

Rewriting equation (2) yields:

Therefore, we need to find the relationship between Qij and the temperature difference at node i to obtain the expression for thermal resistance.

Heat Conduction:

According to Fourier’s Law:

Where l is the characteristic length in m, k is the thermal conductivity in W/mK, and A is the heat transfer area in m2. Substituting equation (4) into equation (3) yields:

Thermal Convection:

According to Newton’s law of cooling:

where h is the convective heat transfer coefficient in W/m2K, Tref is the reference temperature in K, and A is the heat transfer area in m2. Similarly, substituting equation (6) into equation (3) yields:

Thermal Radiation:

Assuming radiation from node i to node j is to a blackbody, i.e., the view factor is 1 (i.e., all energy emitted from node i is absorbed by node j), we obtain:

where ε is the Boltzmann constant in W/m2K4, σ is the emissivity, and A is the heat transfer area in m2. Similarly, substituting equation (8) into equation (3) yields:

Equation (8) is nonlinear with respect to temperature. To evaluate the temperature difference (Ti−Tj), the equation must be linearized. Consequently, the thermal resistance due to radiation is dependent on the node, necessitating iterative calculations to solve the nonlinearity.

Mass Transfer and Heat Transfer:

Consider a pipe with a liquid flowing at known inlet and outlet temperatures Ti and Tj, respectively. The rate of heat exchange as the liquid flows through the pipe is:

where ṁ is the pipe mass flow rate in kg/s, and Cpi is the specific heat capacity of the liquid at the upstream node in J/kgK. Similarly, substituting equation (10) into equation (3) yields:

The equation of thermal resistance varies under different scenarios. Factors such as the choice of coordinate system (e.g., circumferential, axial, and radial directions in cylindrical coordinates), temperature-dependent material properties, and radiative exchange under blackbody assumptions lead to different expressions for thermal resistance. Therefore, when applying thermal resistance, it is essential to ensure the formula aligns with the corresponding physical context.

Calculation Example

The following one-dimensional heat transfer example illustrates the calculation process using the LPTN method.

This example is a one-dimensional heat conduction problem. The dimensions of the solid block are illustrated in Figure 2. The thermal conductivity of the solid block is k = 40W/mK, and T1=T2=293.15K are the boundary temperatures at the left and right ends of the solid block, respectively.

The first step while applying the thermal network method is to discretize the geometry into nodes. A single volume node represents the entire solid block, while boundary nodes represent the boundary conditions at both ends. This yields one volume node (Node 1) and two boundary nodes (Node 2 and Node 3). Connecting these three nodes along the heat transfer path yields the thermal network diagram as shown in Figure 2. In the diagram, PLoss represents the heat sink from the block, and in this case, there is no heat source.

Based on the formula in Section 3, we obtain:

The heat flux between node m and boundary node 1 is:

Similarly, the heat exchange between node m and boundary node 2 is:

where Rth1, Rth2 is the thermal resistance. Since symmetry holds, according to Section (5):

Based on Formula (1), for node:

Substituting equations (12) to (14) into equation (15) gives:

With no internal heat sources and identical temperatures at both boundaries, the theoretical temperature of the entire solid block is also 293.15K, matching the result from the LPTN method.

To discretize the solid block using n nodes for any given node i, an energy conservation equation (i.e., Equation (1)) can be formulated. With n nodes, there will be n linear equations, which can be written as a matrix aij Tj = bi (Ax=b). Using a linear algebra solver, the temperatures at each node can be solved.

When a volumetric heat source is introduced to this solid block, the total heat generation for the entire solid block (as shown in Figure 2) will be applied to a single volumetric node. In this case, using the thermal network method, the temperatures are significantly higher than the theoretical value (the analytical solution obtained from the one-dimensional heat conduction equation), as shown in Figure 3.

When simulating cases with volumetric heat sources, the thermal network method tends to overestimate node temperatures. Therefore, special handling is required for thermal network simulations involving volumetric heat sources to ensure accuracy, and this will be covered in part two.

The LPTN method is a universal approach applicable not only to temperature field calculations but also to fluid flow, electric fields, magnetic fields, and more.

References:

[1] K&K Associates. Thermal Network Modeling Handbook[M]. K&K Associates, 2000.

[2] Dieter Gerling, Gurakuq Dajaku. Novel lumped-parameter thermal model for electrical systems[J]. DAJAKU Gurakuq, 2005.