Modern Electric Vehicles (EVs) demand precise and reliable thermal management to ensure performance, safety, and longevity. However, traditional physical temperature sensors such as NTCs/NTPs significantly increase system cost, require complex wiring, and may be limited in placement flexibility. Virtual Temperature Sensors (VTS) provide a smart alternative by predicting critical component temperatures through physical or deep learning methods, reducing the need for physical sensors while maintaining high accuracy.

Key Benefits for EV Development

📍Beyond Physical Limits:

- Gain thermal insights in locations where physical sensors can’t reach.

- Monitor average or distributed temperatures of components/parts rather than just one spot.

🚀 Future-Ready:

- Unlock opportunities for smarter control strategies and predictive cooling systems.

Objective: Replace Physical Sensors with Virtual Models

The aim of deploying VTS is to reduce sensor count without compromising safety or performance.

Solutions

We provide two different approaches to implement Virtual Temperature Sensors:

- Lumped Parameter Thermal Networks (LPTN): capturing physics-based heat transfer within motors

- Neural Network Models: leveraging data-driven prediction to handle dynamic and nonlinear scenarios.

Physical Methods (Lumped Parameter Thermal Networks)

Physics-based method transforms the motor’s real-world structure into a virtual sensing model. The process is straightforward, transparent, and proven in practice:

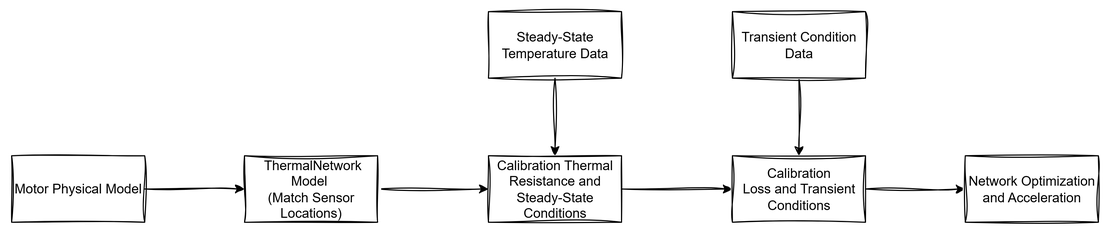

Progress at a Glance

- Motor Model → Start with the motor’s physical structure.

- Thermal Network → Build a network model that reflects heat transfer and sensor locations.

- Calibration → Adjust using steady-state and transient test data to ensure accuracy.

- Model Order Reduction → Simplify for efficient real-time application.

- Optimization → Finalize the model for reliable, fast predictions.

Key Point:

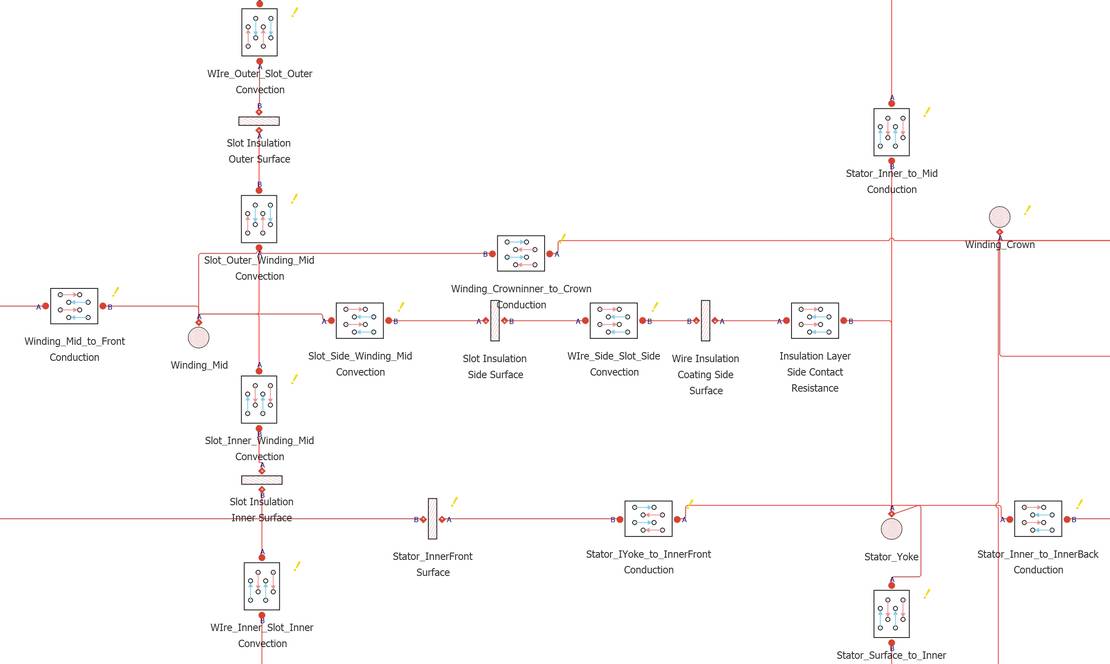

- Physics-based approach ensures accuracy and transparency The process starts with the physical model of the motor, incorporating its geometry, materials, and heat transfer mechanisms. With the Lumped Parameter Thermal Network (LPTN) approach, the system is divided into nodes representing regions such as the windings, shaft, rotor, and stator. Each node is connected by thermal resistances and capacitances, reflecting real pathways of conduction, convection, and radiation. The result is a network model that remains both faithful to physics and straightforward to interpret.

- Simulation-Supported Thermal Modeling

For the construction of the basic thermal model, dedicated simulation tools provide essential support:

- shonDy: Particle based CFD simulation to obtain detailed heat transfer coefficients (HTCs) on critical surfaces such as windings, rotor, shaft, and stator.

- shonTA: LPTN model simulation uses HTC data as input to build the Lumped Parameter Thermal Network (LPTN), translating physical behavior into an efficient nodal representation suitable for calibration and further optimization.

This combination of CFD-based data acquisition and network modeling ensures that the thermal model is both data-informed and computationally efficient.

Calibrated with real-world data

To ensure predictive accuracy, the thermal network model is calibrated using test measurements. Steady‑state tests align thermal resistances so that predicted temperatures match measured equilibrium values. Transient tests refine heat capacities and loss parameters, enabling the model to reproduce realistic thermal dynamics during load changes. Through this calibration process, the virtual sensor reflects both the underlying physics and the real operating behavior of the motor, providing trustworthy results for design and operation.

AI Method

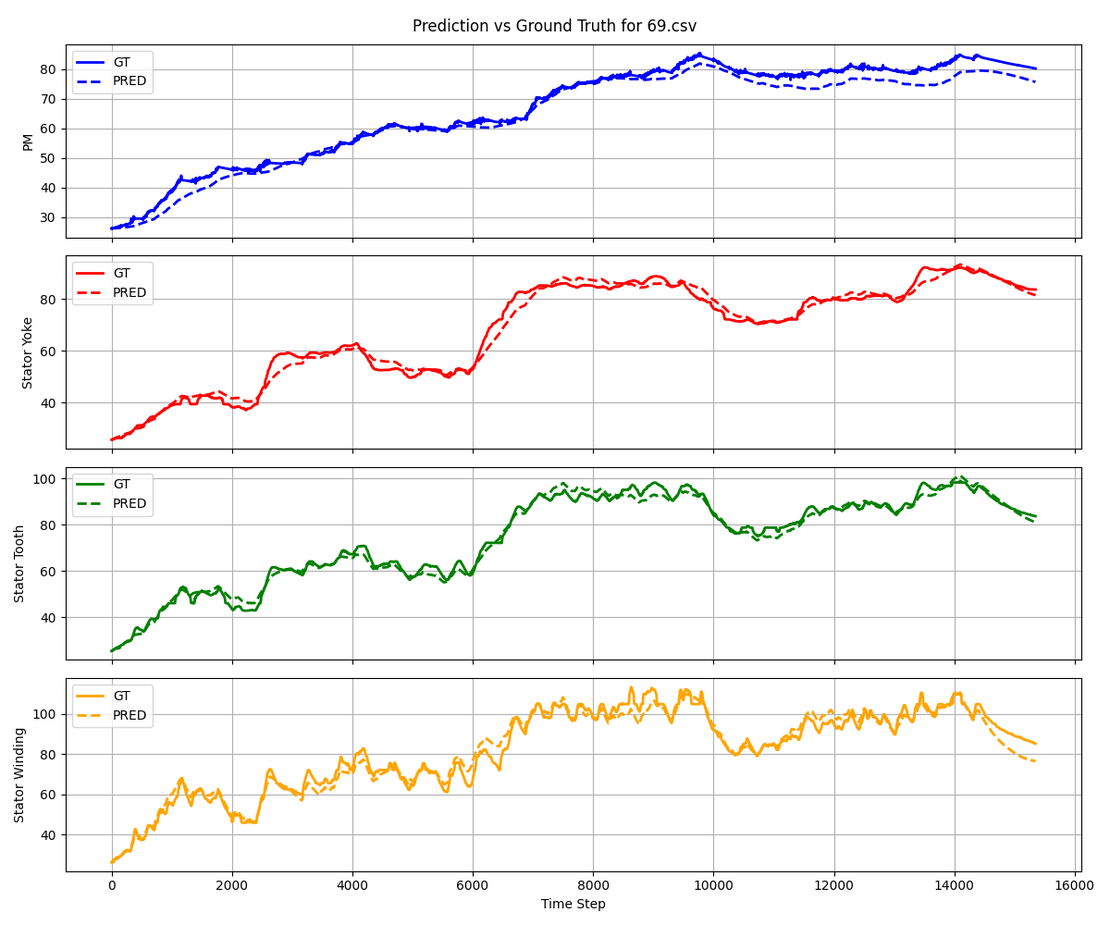

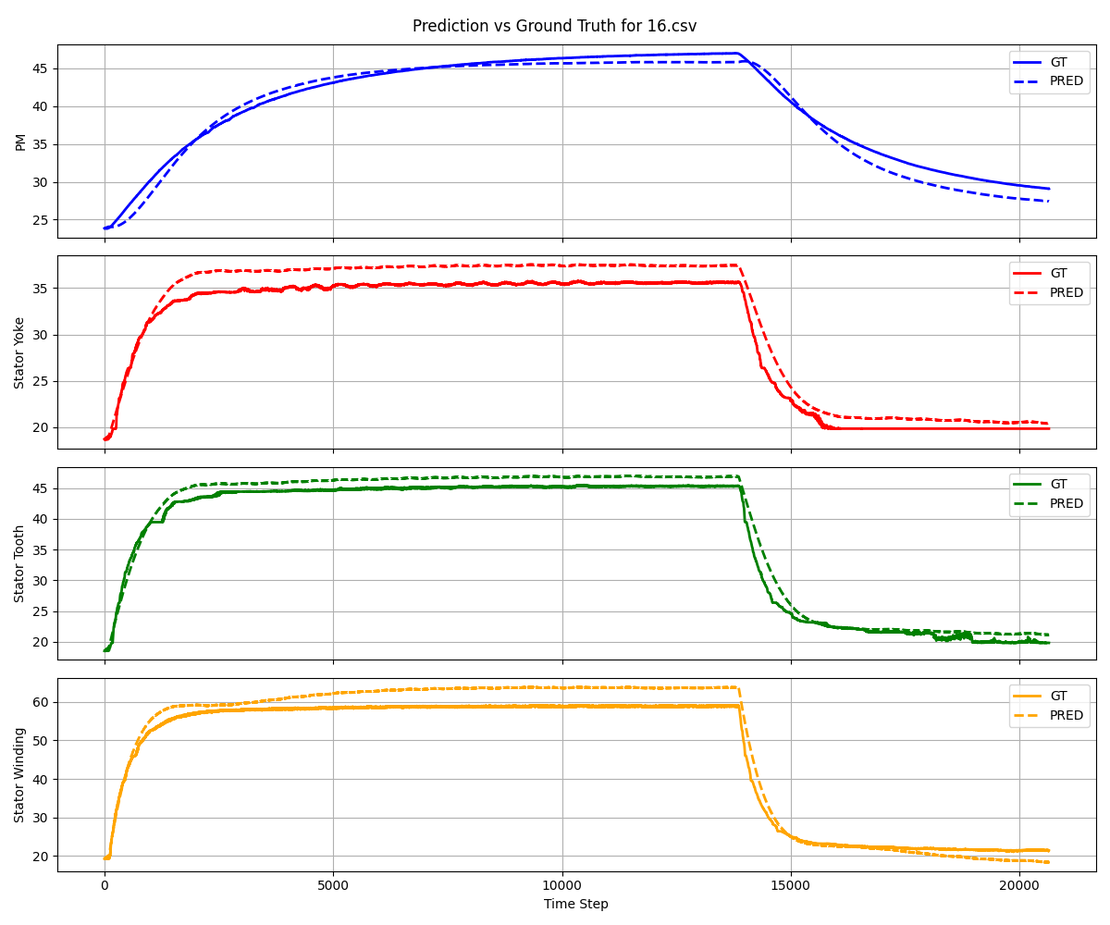

The AI approach leverages data-driven modeling to predict the thermal behavior of the motor. Historical and real-time operational signals — such as current, voltage, speed, and ambient temperature — are collected and transformed into inputs for machine learning algorithms. These models capture the nonlinear relationship between measurable signals and internal motor temperatures, including locations beyond sensor reach.

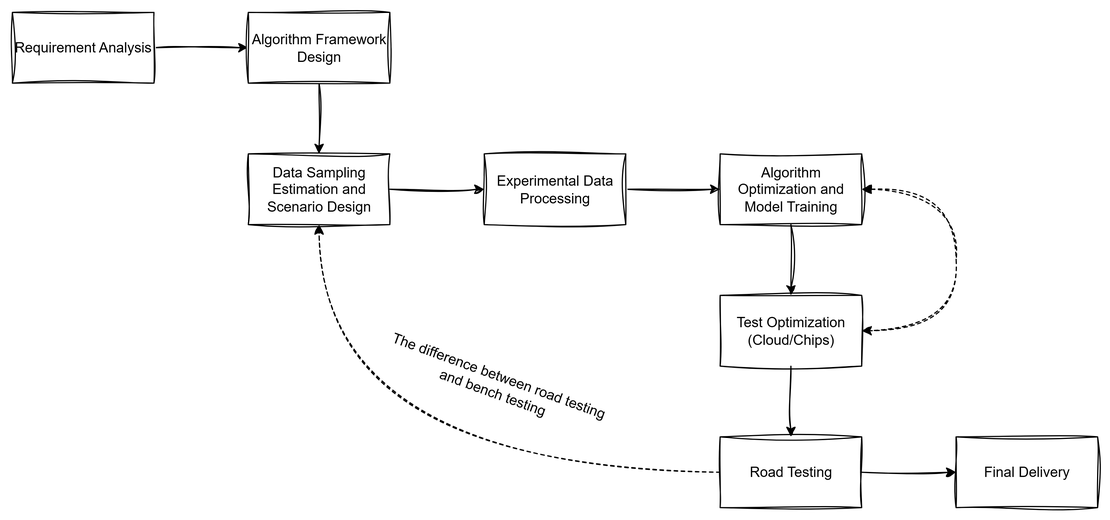

The AI-based approach relies on the following steps for implementation:

Data Collection: Gather operational data from the motor under various conditions, including steady-state and transient operations. This data should encompass measurable signals like current, voltage, rotational speed, and ambient temperature, as well as temperature readings from physical sensors for validation purposes.

Feature Engineering: Extract relevant features from the collected data to improve predictive accuracy. This step may involve processing raw signals, identifying key patterns, and creating additional variables that represent the underlying thermal behavior of the motor.

Model Training: Use the processed data to train machine learning models, such as neural networks, to predict internal motor temperatures. These models are designed to capture complex, nonlinear relationships between input signals and target temperatures, even in scenarios where traditional physical models may struggle.

Validation and Optimization: Validate the trained model against a separate dataset to ensure high accuracy and robustness. Hyperparameter tuning and optimization techniques are applied to refine model performance and reduce prediction errors.

Deployment: Integrate the trained AI model into the motor’s control system for real-time operation. This includes ensuring the model is lightweight enough for efficient execution on embedded systems while maintaining predictive accuracy.

Key Advantages of the AI Method:

Dynamic and Nonlinear Behavior: Unlike traditional methods, AI models excel at capturing the complex, dynamic interactions within the motor system, such as rapid load changes and varying environmental conditions.

Scalability and Flexibility: AI-based virtual sensors can be easily adapted to different motor designs and operational scenarios without requiring extensive physical modifications.

Reduced Development Time: Once the initial data and model-building framework are established, new virtual sensors can be developed more quickly compared to physics-based approaches.

Reference Data for model training used in this post was taken from: https://www.kaggle.com/datasets/wkirgsn/electric-motor-temperature