洗碗机的性能对于高效彻底的清洁至关重要,尤其是在现代家庭和工业应用中。 通过模拟内部水流动力学,工程师可以优化喷嘴的布置、喷射模式和流量,确保水流能够有效覆盖所有餐具表面。 这种方法不仅提高了清洁效率,还有助于减少水和能源的消耗。 借助shonDy,这些优化可以快速而准确地实现,使其成为设计和改进洗碗机系统的重要工具。

在这种情况下,目的是将模拟结果与实验结果进行比较。

几何形状

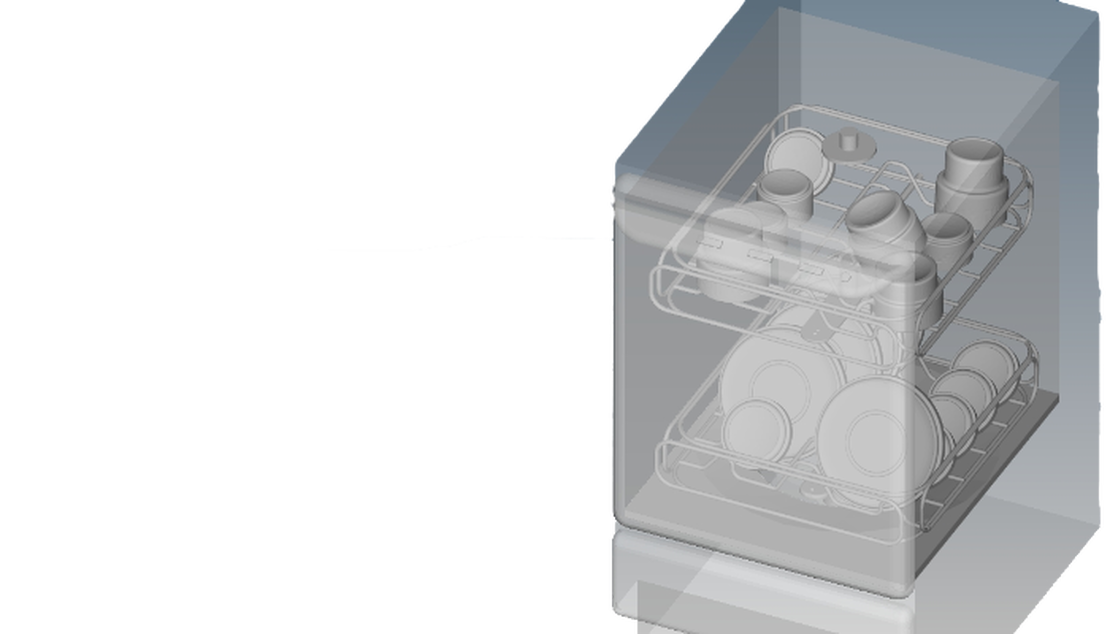

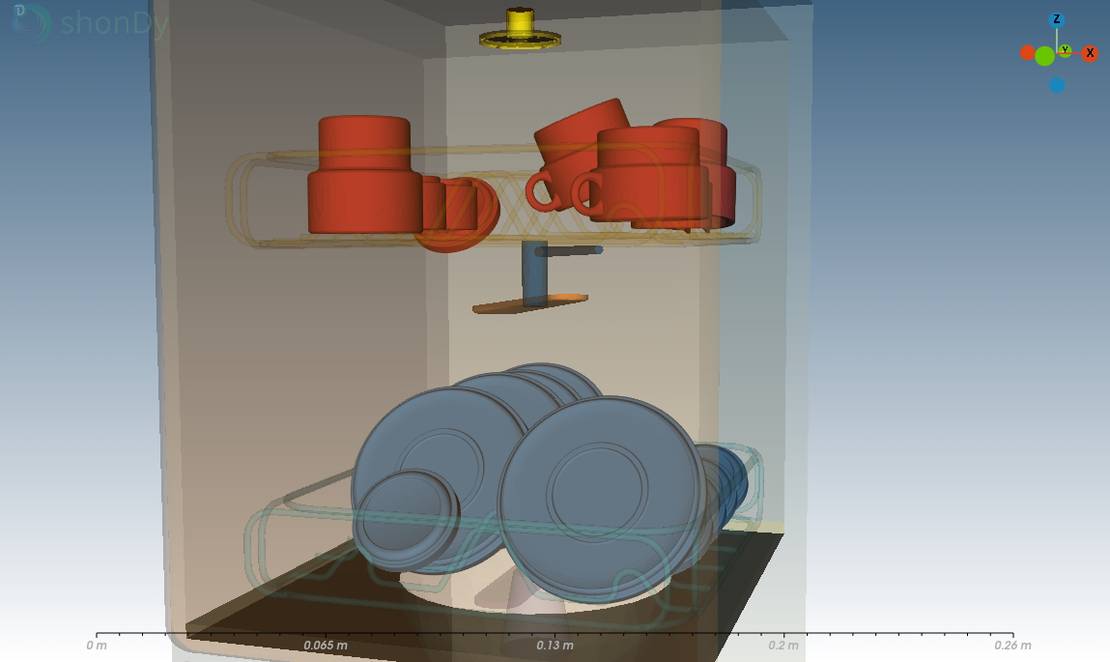

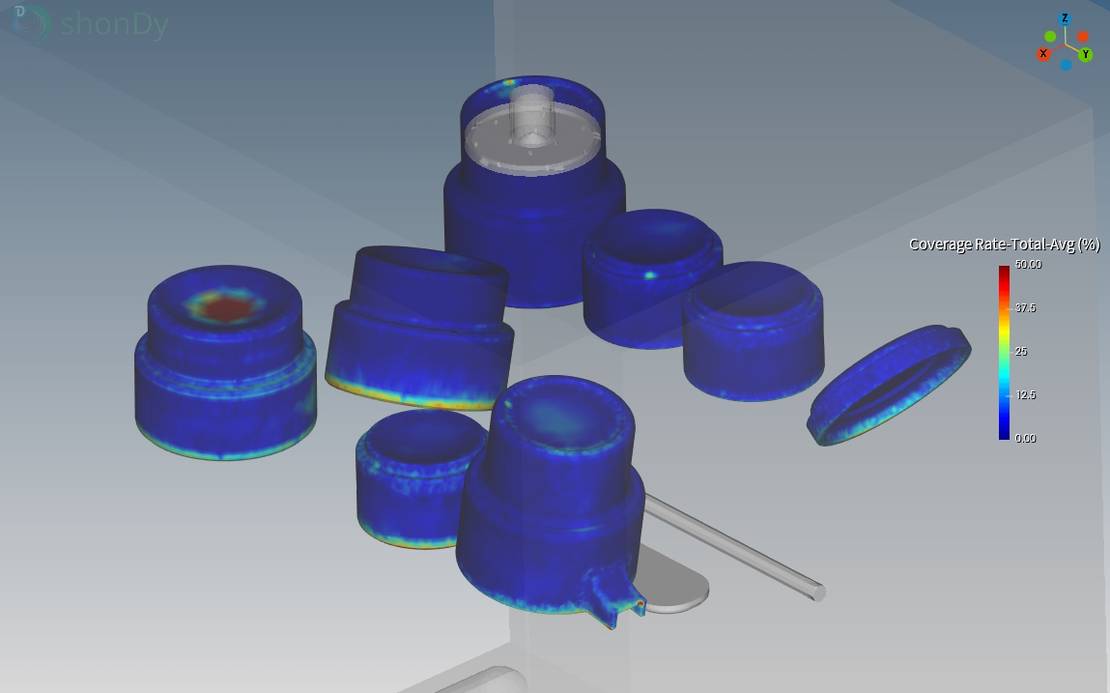

本案例中的洗碗机几何模型基于GrabCAD上的公开设计,代表了一种经典的老式型号——甚至可以称之为“过时”的设计。 尽管它并未体现最新的创新技术,但这种几何结构非常适合展示shonDy的功能。 其简洁性突出了优化过程的起点,以及shonDy如何推动改进。 通过关键特性如喷臂优化、水流分布和覆盖分析,shonDy展示了其如何快速、精准地提供优化结果。

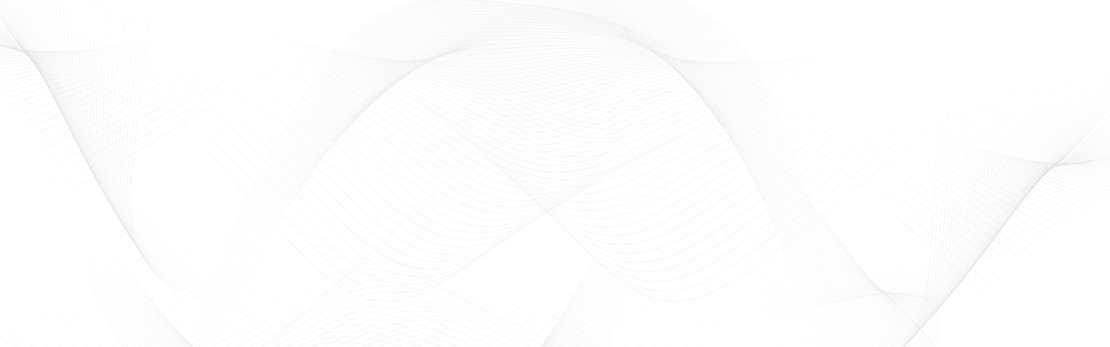

除了基础几何结构外,我们还引入了多项增强功能以丰富仿真内容。 这些增强包括在上层隔间中增加了两个喷臂、一个顶部喷淋装置,以及一个经过改进的洗碗机底部设计,旨在优化水流管理。 当然,洗碗机仿真中不可或缺的是餐具的布置——它们被 strategically placed 以评估水流覆盖范围和清洁效率。 这些新增内容展示了shonDy如何处理复杂配置,并为优化提供深入见解。

案例设置

仿真覆盖了总计17秒的实际运行时间,准确模拟了洗碗机的交替喷淋系统。 在此设置中,底部喷臂在0到10秒期间单独运行,而上部喷臂和顶部喷淋则在10到17秒期间接管工作。 喷臂的旋转速度设置为45 RPM,顶部喷淋的旋转速度为135 RPM,以复现真实操作条件。 流体粒子的半径设置为0.0004米。

入口和出口处理

入口 - 底部喷臂

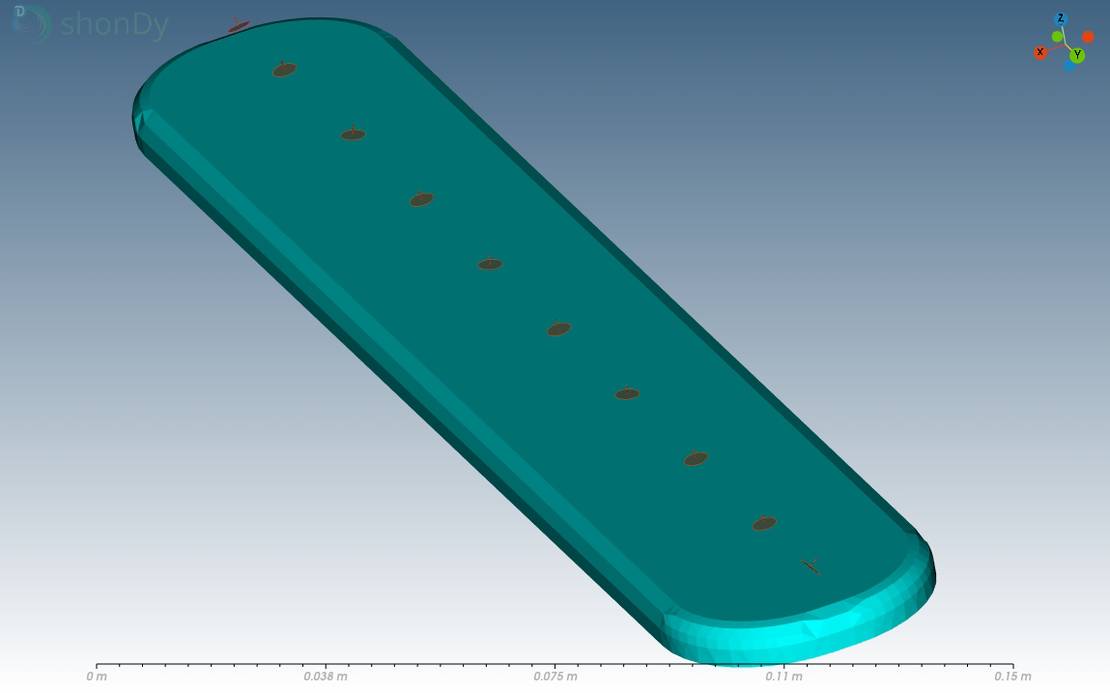

喷臂喷嘴被建模为10个独立的入口,每个入口的半径为0.002米。 中央的8个喷嘴主要朝上,并带有轻微的侧倾,在x-z平面内以±6°的角度交替倾斜,以实现更好的覆盖范围。

两个边缘入口具有特殊功能:

- 一个朝上并与喷臂切向对齐,模拟负责产生旋转冲力的喷嘴。

- 另一个朝上并与喷臂径向对齐。

外部喷嘴的流量为3.65升/分钟,而中央喷嘴的流量为2.92升/分钟。 总流量达到30.6升/分钟。

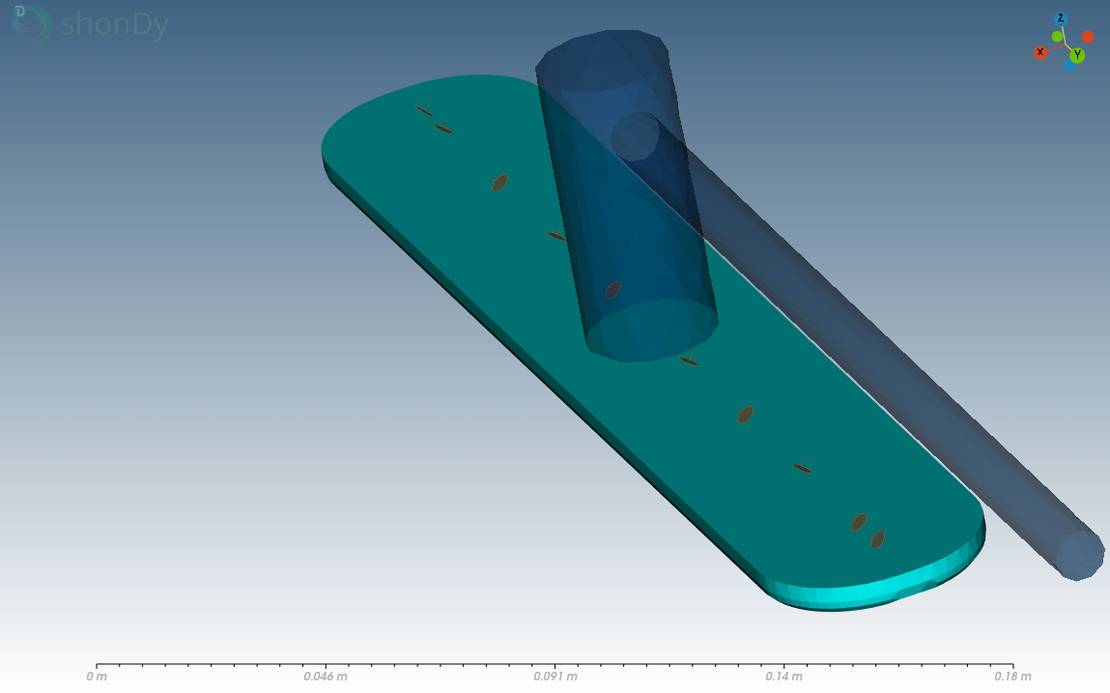

入口 - 上部喷臂

上部喷臂同样设有10个入口,但由于支撑臂的设计,其配置略有不同。 此外,它们的倾斜角度更大:两个外部喷嘴在旋转方向上倾斜45°,而中央喷嘴则以±35°的角度交替倾斜,确保优化水流分布和动态覆盖。

冲力喷嘴的流量为2.38升/分钟,中央喷嘴的流量为1.9升/分钟。 这些入口的总流量约为20升/分钟,提供高效且有效的水流覆盖。

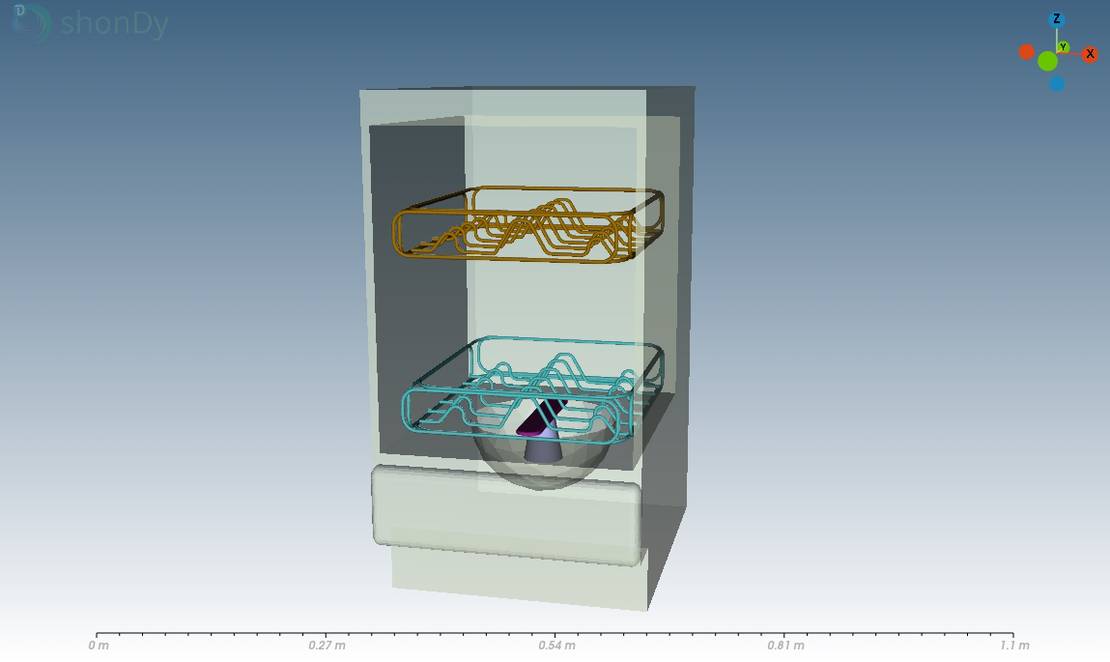

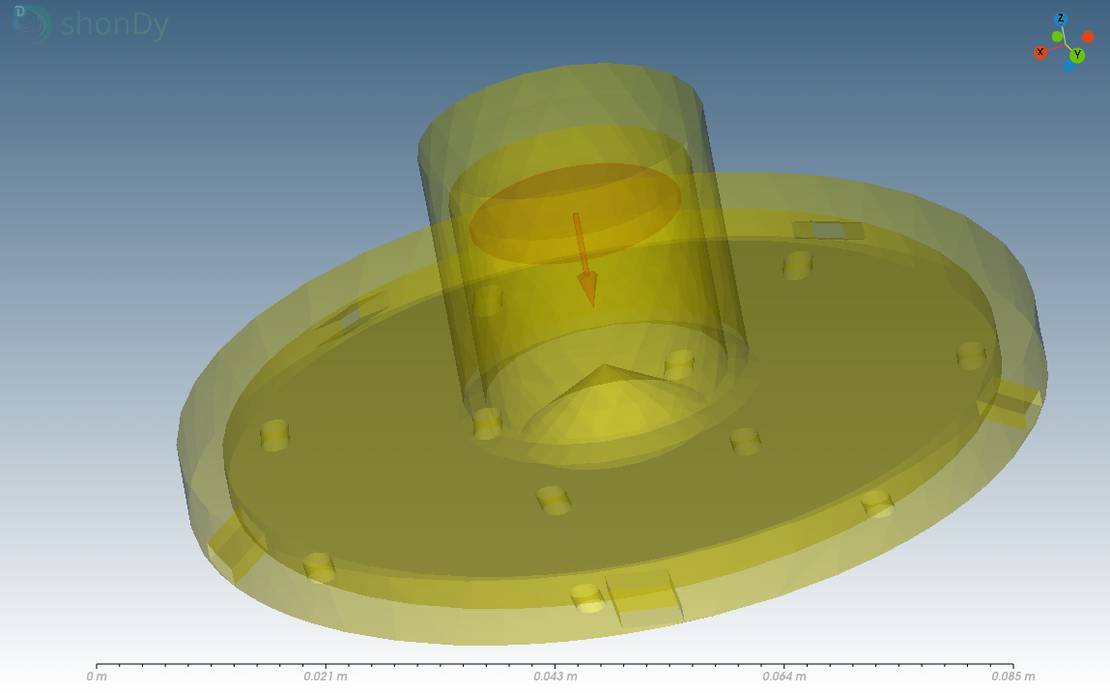

入口 - 顶部喷淋

顶部喷淋的设计与喷臂不同。 它没有多个喷嘴,而是采用一个半径为0.01米的单一大型入口。 水流分布通过旋转的物理几何结构实现,其旋转速度为135 RPM。 顶部喷淋的流量设置为7升/分钟,提供集中且高效的喷淋模式。 (请参见下图,以获得直观展示)。

出口

出口位于底部喷臂下方,用于移除不再参与洗碗过程的流体粒子。 其主要目的是限制仿真中的流体粒子总数,确保计算过程更高效且易于管理。

仿真结果

覆盖率作为效率指标

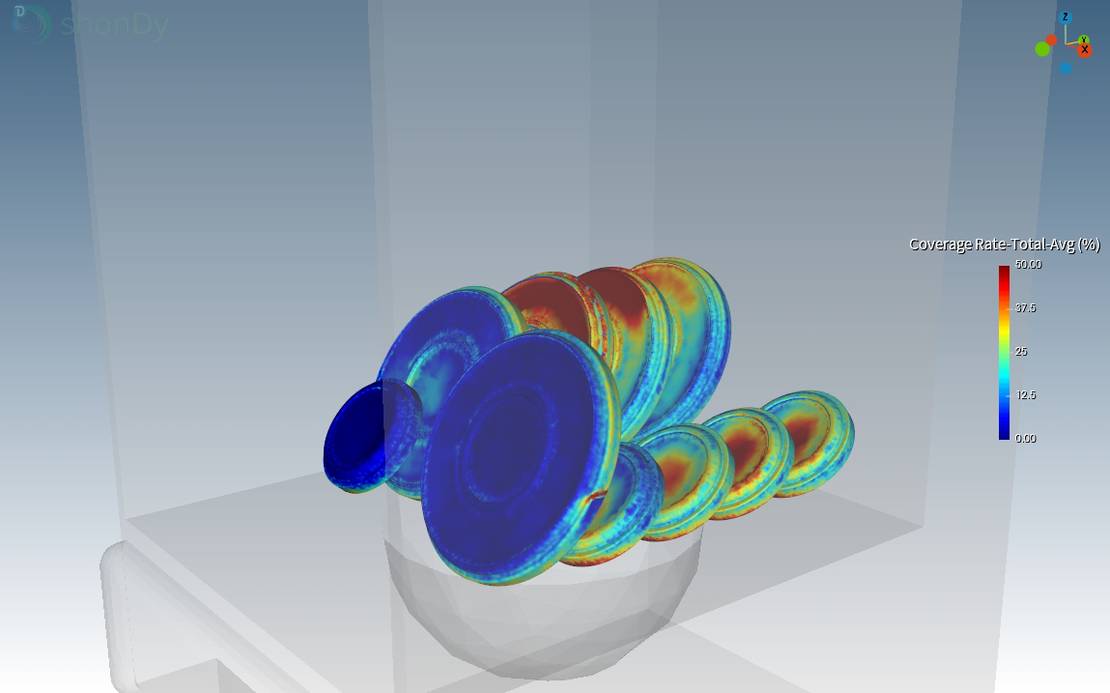

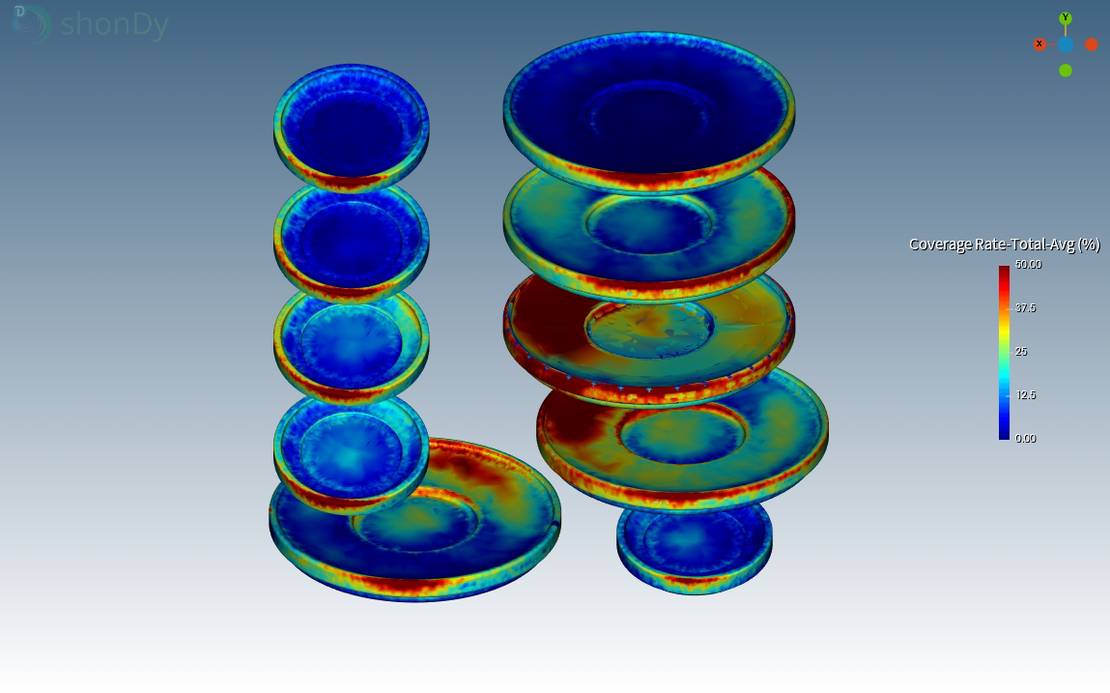

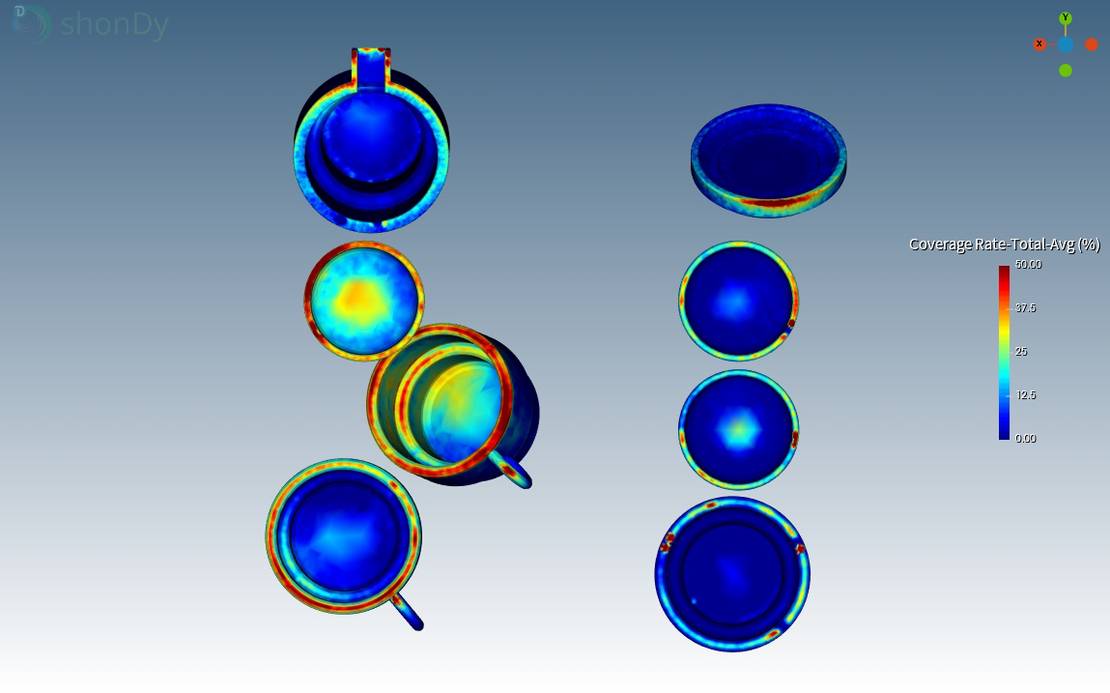

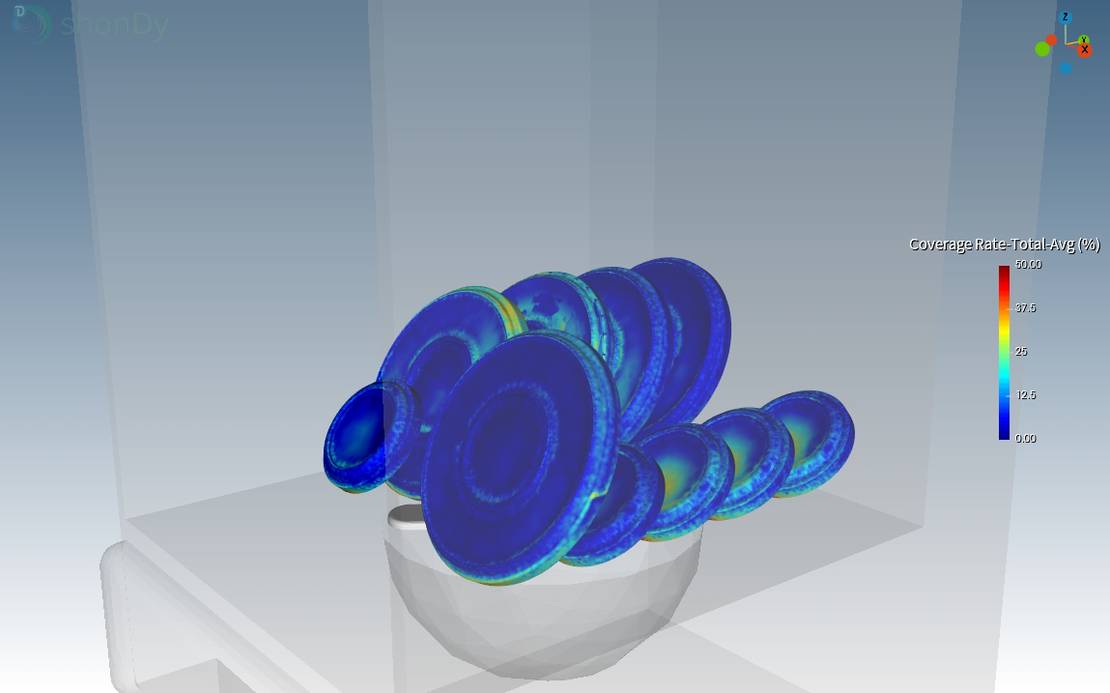

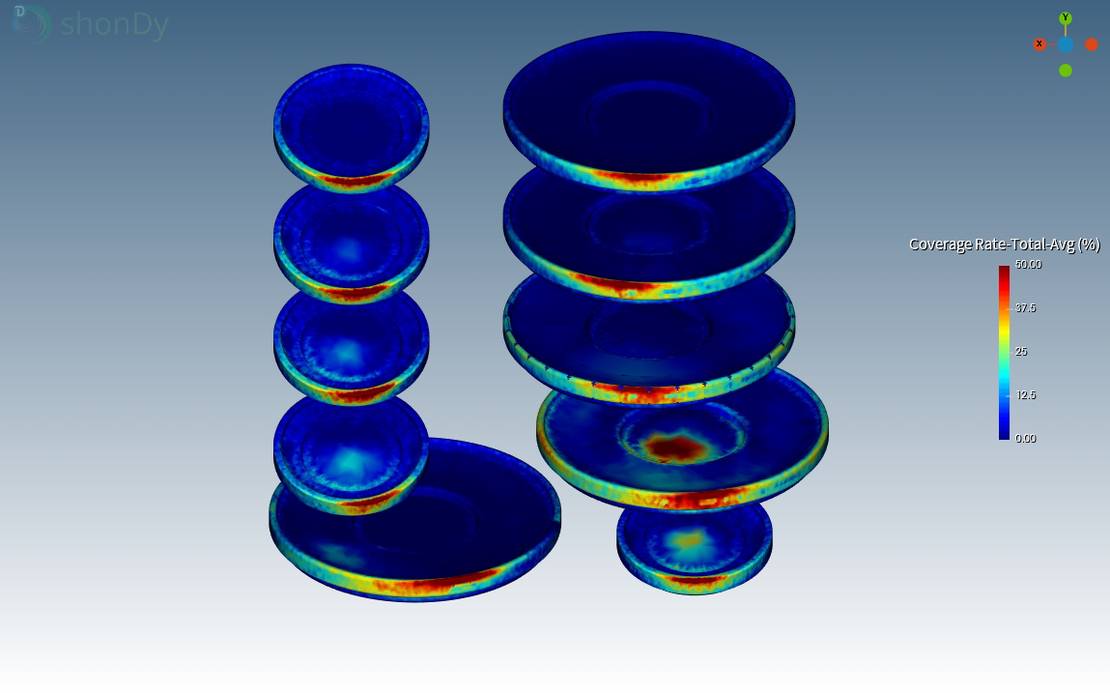

为了量化洗碗机的效率,仿真在特定时间点(10秒和15秒)评估了餐具的覆盖率。 下图展示了上下层餐具在5秒内的平均覆盖率。 这一指标为水流分布的有效性和清洁的彻底性提供了重要见解。 换句话说,50%的平均覆盖率意味着餐具平均有50%的时间与水接触。

10 秒后的结果

在前10秒内,仅底部喷臂处于工作状态。 这反映在覆盖率上,下层隔间的餐具比上层隔间的餐具湿润得更好。 这清楚地表明,如原始几何结构所示,仅依赖底部喷臂无法实现最佳清洁效果。 然而,即使在下层隔间内,仍有部分区域未被湿润或覆盖不足, 这表明液体分布不够理想。 可能的原因包括底部喷臂尺寸过小、下层餐具架距离喷臂过近,或喷嘴数量不足或位置未优化。

15 秒后的结果

15秒后的结果如下所示。 在此期间,仅上部喷嘴处于工作状态。 正如预期的那样,上层隔间的分布有所改善,但总体变化较小。 上层隔间的湿润情况更好,但类似的问题仍然存在。 部分区域的水流覆盖仍然不足,表明水流分布尚未达到最佳状态。

洗碗机中的水量

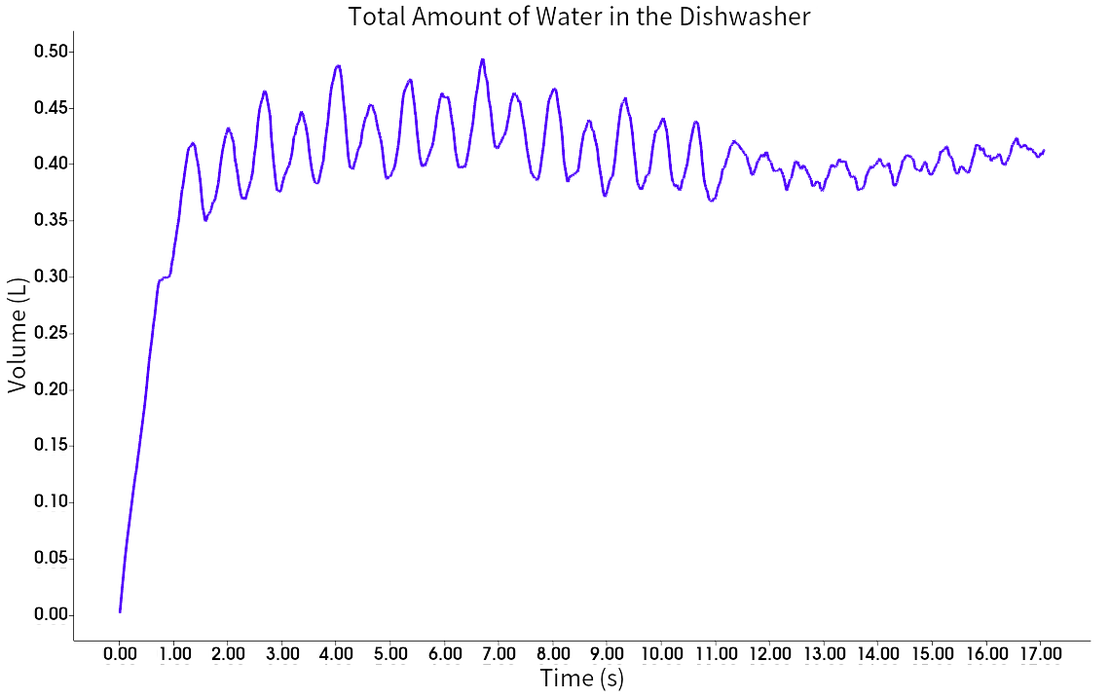

下图显示了随时间变化的总水量。 可以看出,仿真中任何时候的水量都不超过0.5升。 这意味着,即使流量恒定在 30 升/分钟左右,水也能很快排出。 在实际洗碗机中,回流的水会被重新利用并通过喷嘴重新分配以进行清洁。

总结

本次仿真展示了shonDy能够真实模拟洗碗机,准确复现其交替喷淋系统,并提供优化所需的关键参数。 仿真的总运行时长为17秒,其中底部喷臂在0到10秒内工作,上部喷臂和顶部喷淋在10到17秒内工作。 喷臂的旋转速度设置为45 RPM,顶部喷淋的旋转速度为135 RPM,以复现真实操作条件。 流体粒子的半径为0.0004米。

在整个仿真过程中,分析了喷臂配置、喷嘴流量和覆盖率等关键因素。 结果表明,尽管底部喷臂在下层隔间表现良好,但仅依赖其无法实现最佳清洁效果,这凸显了交替喷淋系统的重要性。 仿真还提供了关于水流分布的见解,重点关注覆盖率,这是评估清洁效率的关键指标。

本次仿真的目标并非优化洗碗机本身,而是展示shonDy的功能。 所呈现的仿真作为优化任务的起点,展示了shonDy通过详细的流体动力学建模和快速精准的分析提升设备性能的潜力。